-

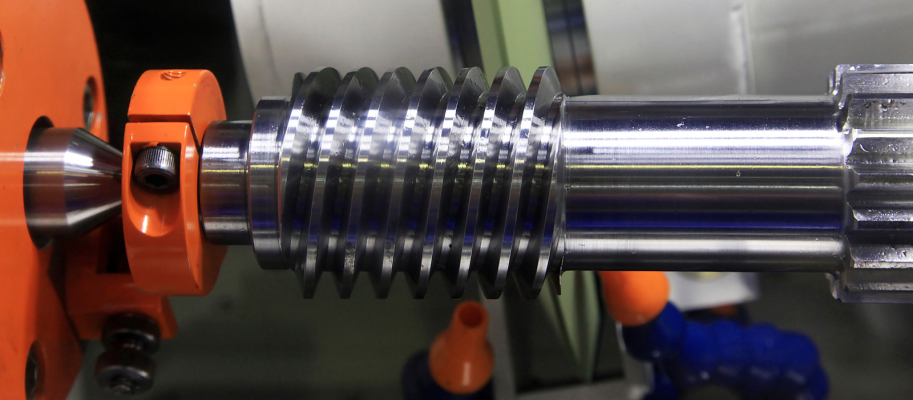

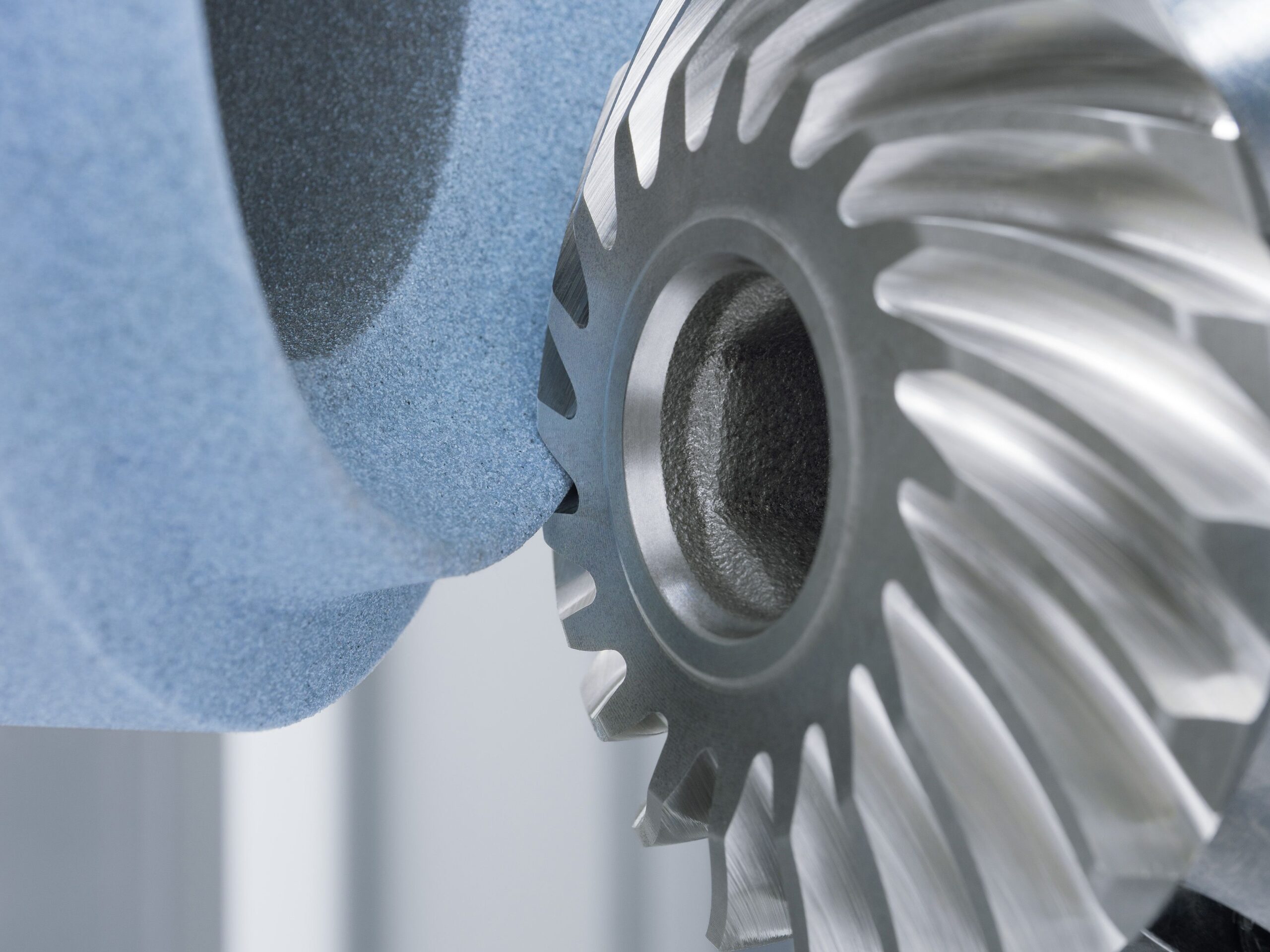

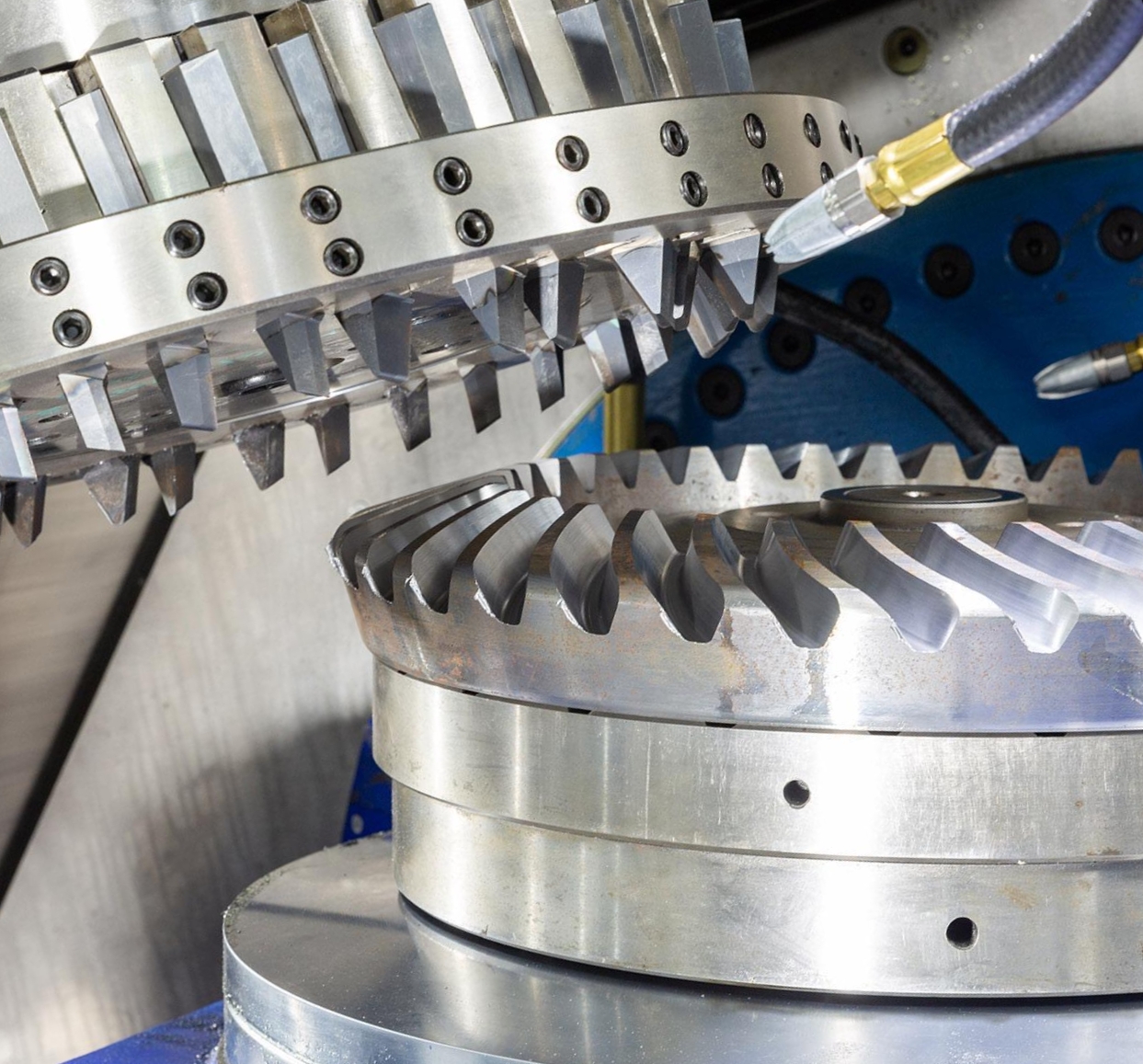

Hochgenaue Lösungen für Verzahnungsmaschinen

ww-cnc technology GmbH

Verzahnungstechnologien mit maximaler Präzision

Je nach Kundenwunsch liefert ww-cnc technology Komplettlösungen für die Modernisierung von Verzahnungsmaschinen bestehend aus einer vollständig neuen Elektrik sowie der mechanischen Überholung. Die firmeneigene Software für verschiedene Verzahnungstechnologien hat sich sowohl in nachgerüsteten als auch in neuen Maschinen von weltweit führenden Herstellern bestens bewährt.

Während langjähriger Tätigkeit in der CNC – Softwareentwicklung und Maschinenmodernisierung hat sich das Team das Knowhow erworben, das erforderlich ist, um mit hochwertigen Lösungen ein Höchstmaß an Genauigkeit und Produktivität zu erreichen. Für die Modernisierung der Maschinen unterstützen kompetente Partner im Bereich der Elektrik und Mechanik.